The Toughness for Fiber Composite PE Pipes

Pipe failure in long-term applications is characterised by creep crack initiation and creep crack growth. Both can be determined by fracture mechanics-based tests of the pipe materials. Nowadays, several accelerated tests are available:

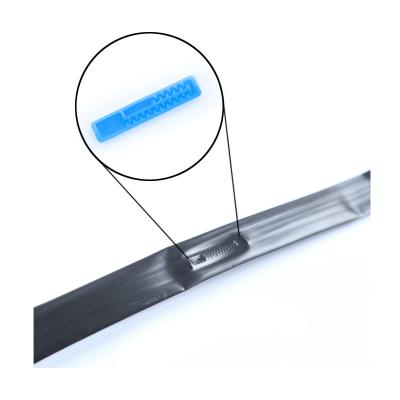

Considering new fiber composite polyethylene (pe) substances are contemplated for use by means of fuel industry, a chief assignment is to carry out a computational evaluation for the cracked and uncracked pipes. That is completed using a completely unique finite detail code pfrac. The initial development of the pfrac model was for isotropic pipe materials. the modifications described here element a recent enhancement to don't forget the anisotropic pipe material, to simulate and analyze the dynamic and laminate conditions for the fiber composite pe fabric gas pipelines. In line with the check records of material materials, numerous numerical examples are given to demonstrate the overall performance of the fiber pe pipes. In comparison with pure pe pipe, the hoop displacements are decreased from 53% for pipes with random short fibers to five% for pipes with fibres wound at 80 degrees to the pipe axes; the crack driving forces are also reduced from 50% to 17%, respectively.