Description of drip irrigation

I. Composition of the microirrigation system

The micro-irrigation system is composed of water source, front hub, water transmission and distribution pipe network, irrigation device, flow rate, pressure control parts and measuring instrument.

1. Water source

Rivers, channels, lakes, reservoirs, wells and springs can be used as microirrigation water sources, and their water quality should meet the requirements of microirrigation.

2. Front hub

The front hub includes water pump, power engine, fertilizer and pesticide injection equipment, filtration equipment, control valve, inlet and exhaust valve, pressure and flow measuring instrument, etc.

Water pumps commonly used for micro-irrigation are submersible pump, centrifugal pump, etc.Power engine can be diesel engine, electric motor, etc.Of course no pumps are needed where there are enough natural heads.

When the water supply requires storage or sandy water, reservoirs and sedimentation tanks are required.The sedimentation tank is used to remove large solid particles from the water source, and to avoid algae production in the sedimentation tank should be covered or shaded.

The function of the filter equipment is the filtration of the solid particles in the irrigation water to avoid the blockage of the system.Fertilizer and pesticide injection equipment is used to add fertilizers, herbicides, pesticides, etc., directly to the microirrigation system, and the injection equipment shall be set before the filtration equipment.

Flow and pressure measurement gauges are used to measure the flow or pressure in pipelines, including water meters and pressure gauges.The water meter is used to measure the total amount of water flowing through the pipeline, which can be installed in the part or on any dry or branch pipe as needed.If installed in the section, it must be installed before the fertilization device to prevent fertilizer corrosion.The pressure gauge is used to measure the internal water pressure in the pipeline, and a pressure gauge is set before and after the filter and the sealed fertilization device to observe the pressure difference to determine whether the amount of fertilizer applied and whether the filter needs to be cleaned.

The controller is used to automatically control the system. Generally, the controller has the timing or programming function to operate the solenoid valve according to the instruction given by the user.

Control valves generally have gate valve, reverse check valve, air valve, solenoid valve, etc.

3. Water transmission and distribution pipe network

The role of the water transmission and distribution pipe network is to transfer the water treated by the hub to each irrigation unit and irrigation, and the water transmission and distribution pipe network consists of dry, branch pipe and wool pipe.The wool pipe is the last pipe of the microirrigation system on which the irrigation is installed or connected.

4. Water irrigation apparatus

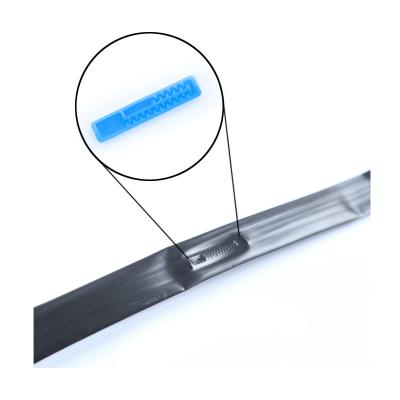

Irrigation is the part of micro irrigation equipment, is directly to the crop irrigation equipment, its role is the final pipe (wool pipe) pressure flow evenly and stably poured into the soil near the crop root area, reduce pressure into water droplets or fine flow or spraying into the soil, irrigation quality directly affects the life of micro irrigation system and the quality of irrigation.There are many kinds of irrigation devices, each with its own characteristics and different applicable conditions.

Requirements for irrigation device: manufacturing deviation is small, generally requires the manufacturing deviation of irrigation device is controlled below 0.07; water output is small and stable, less affected by water head change; strong blockage resistance; simple structure, easy manufacturing, installation, cleaning; strong, durable, low price.

According to the different structure and outflow form, the irrigation mainly includes 6 types of drip, micro sprinkler head, micro spray belt, drip irrigation belt (pipe), gushing (small pipe outlet) and seepage pipe.Most sprinklers are made with plastic injection molding.

II. Classification of microirrigation system

According to the different irrigation device, the micro-irrigation system is divided into a drip irrigation system and a micro-sprinkler irrigation system.Based on whether the water distribution pipeline can be moved during the irrigation season, the microirrigation system can be divided into fixed, semi-fixed and mobile type.

The components of the fixed micro-irrigation system are fixed throughout the whole irrigation season. The dry pipes and branch pipes are generally buried underground. According to the conditions, some wool pipes are buried underground, and some are placed on the surface or hanging on the bracket dozens of centimeters high from the ground.Fixed microirrigation systems are commonly used for more valuable cash crops.

The front hub and stem and branch pipes of the semi-fixed microirrigation system are fixed, and the wool pipe and irrigation device can be moved.A wool tube can work in multiple locations.There are also two advantages: one is beneficial to agricultural machinery operation; the other is conducive to crop rotation, such as quarterly strawberry planting, folding away mobile drip irrigation facilities can plant rice.

All components of the mobile microirrigation system are movable.Irrigation and installed at different locations in the irrigation area.Semi-fixed and mobile microirrigation systems improve the utilization of equipment and reduce investment per unit area, commonly used in field crops and cash crops requiring crop rotation.